fda - approved facilities

FDA - APPROVED FACILITIES

USDA & ADA Facility Services

Procoat handles coatings and prep work in USDA-regulated and ADA-compliant facilities. We

understand what it takes to work in food-grade, health-sensitive, and federally regulated

environments-and we take it seriously.

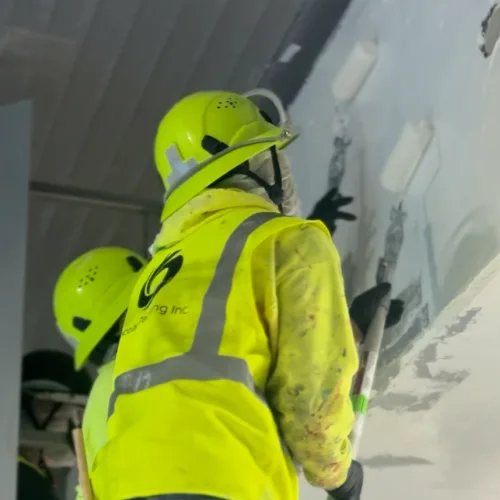

We lead every shift with a safety meeting. Our crew follows strict PPE use, hazard communication,

and site-specific safety plans. We’re proud of our safety record, and we hold each team member

accountable to maintain it. We follow OSHA and EPA protocols without shortcuts.

What We Offer

- Sandblasting & Containment

- Ultra-high-Pressure Water Blasting (Up to 40,000 PSI)

- Interior & Exterior Coatings

- Tank Coatings & Liners

- Batch Room Ceilings & Wall System

- Equipment Coatings & Line Markings

- Facility Painting from A to Z

Regulated Work Environments

We meet USDA facility standards with approved coatings that resist mold, bacteria, and chemical

damage. All work is done cleanly, with full containment if needed. In ADA-regulated areas, our work

never interferes with accessibility or layout compliance. We’re mindful of every code requirement.

Deadlines & Shutdowns

We work during planned shutdowns and coordinate tightly with facility staff. If work must be done

overnight or in phases, we build that into the schedule. Procoat respects the goals of each

facility-production uptime, cleanliness, and job completion. We meet the deadline. Pe.

Frequently Asked Questions

We offer a wide range of industrial coatings designed to protect equipment and infrastructure in power generation plants. Our solutions include corrosion-resistant coatings, high-temperature coatings, chemical-resistant coatings, and insulation coatings tailored to thermal, hydro, nuclear, and renewable energy facilities.

Our advanced coatings provide a protective barrier against corrosion, extreme temperatures, and chemical exposure. This reduces maintenance costs, prevents premature wear, and enhances operational efficiency, ultimately extending the lifespan of turbines, pipelines, cooling towers, and other critical components.

Yes, our coatings are engineered to withstand harsh environments, including high humidity, salt exposure, UV radiation, and extreme temperatures. We ensure that our solutions meet industry standards and provide long-term durability for power plants operating in demanding conditions.

Absolutely! We understand that each power plant has specific needs. Our team works closely with clients to develop tailored coating solutions that address unique challenges, ensuring optimal protection and performance for their equipment.

You can contact us through our website or call our expert team for a consultation. We’ll assess your facility’s needs, recommend the best coating solutions, and provide a detailed quote to ensure maximum protection and efficiency for your power generation operations.

Our Commitment to Excellence

We collaborate closely with coatings representatives and engineers to ensure the appropriate products are selected for each specific area. Comprehensive documentation—including batch logs, DFT reports, and inspection records—is always readily available. From ceilings to tank linings, Procoat delivers a complete, end-to-end solution